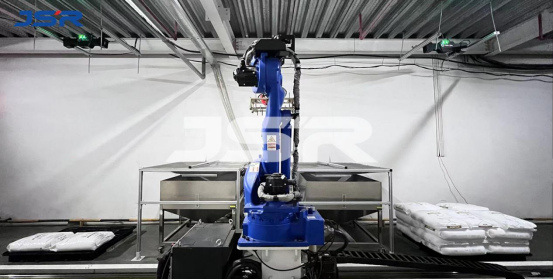

JSR’s robotic handling process automation with YASKAWA handling robot is applied in the handling and unpacking of plastic particle bags, its accurate, reliable and sustainable handling operation, contributing value to promote production automation.

No matter in the aspects of machinery, agriculture, clothing, construction or daily life, we can see the figure of recycled plastic particles. After packaging, these particles need to be handled manually, which is an intermittent work with high cost and high labor intensity. The customer’s previous working time was 8 hours, and each bag of materials was 25Kg. The manual efficiency is 2 bags per minute, and 960 bags can be disassembled in a day. The working time after robot handling and disassembling is 24 hours, which can be operated continuously, and the efficiency is 3 bags per minute, and 4320 bags can be disassembled in a day.

The solutions implemented by Jiesheng for customers: Yaskawa handling robot GP180, 7.5m long ground rail, material bin, material rack, GP180 maximum load 180kg, maximum arm span 2702mm. 7.5m earth orbit effective travel is 6m, moving speed is 0.7m/s. 3D visual identification blanking system. 3D visual identification blanking system, camera with learning function, through the early material data acquisition and later material modeling, so that the success rate of camera recognition is 99.9%.

Automatic production greatly improves work efficiency, stable production capacity, accurate delivery, high safety, reasonable use of the existing area, improve the corporate image and workshop cleanliness, to achieve unmanned production.

Post time: Sep-26-2022