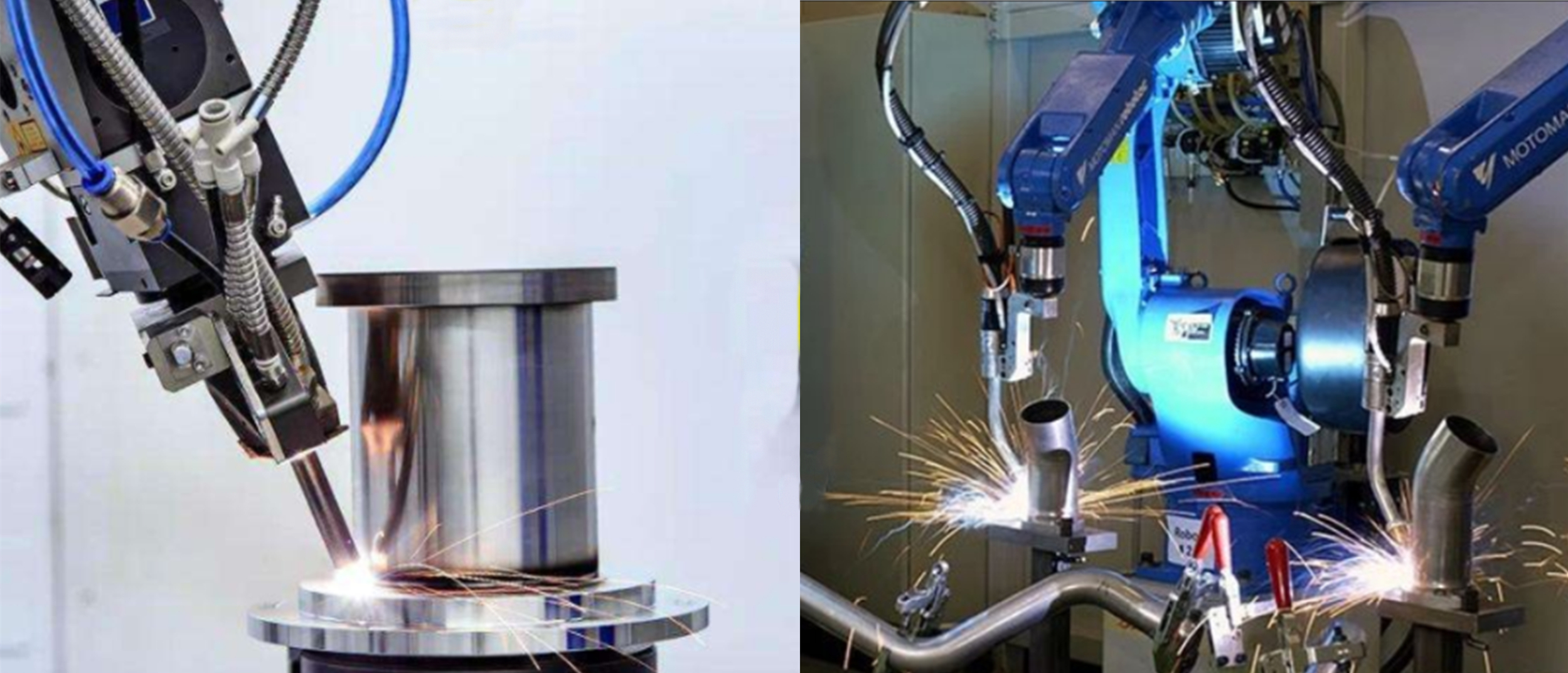

Robot laser welding system is composed of welding robot, wire feeding machine, wire feeding machine control box, water tank, laser emitter, laser head, with very high flexibility, can complete the processing of complex workpiece, and can adapt to the changing situation of the workpiece. The laser system can use a welded lens, a cut lens, a scanned welded lens or even a laser cladding, which is magnetically coupled so that different lenses can be quickly switched between each other.

Robot laser welding system is widely used in automobile manufacturing, engineering machinery, electronics industry, aerospace, municipal construction and other fields. Users choose the process according to their own work pieces when using.

Laser welding system features:

1. High welding precision. The laser beam spot of the robot laser welding machine is small, the heat affected zone is small in the welding work, for different welds, the laser beam can ensure the quality of the weld, the workpiece is not easy to produce deformation, cracks and other welding defects, laser welding pool can purify the weld metal, the mechanical property of the weld is equivalent to or better than the base metal. Visual system can be equipped to realize accurate positioning before welding.

2. Improve welding efficiency. A robot laser welding machine can achieve uninterrupted production after starting, if the user realizes laser welding production line, including workpiece loading and unloading, palletizing, handling and other actions, can replace 3 to 4 resistance welding robots, if the full use of laser welding technology, can realize the intelligent production of the whole production line, improve welding efficiency.

3. Strong versatility and extensibility, it can carry different models of robots according to needs, to meet the requirements of different precision and load. There is no requirement on the workpiece material, can be welded various materials, such as aluminum, carbon steel, stainless steel, etc.

4. Suitable for thin plate welding, laser welding machine is to melt welding materials through laser, but laser is a short plate in depth welding. It’s not that laser deep welding isn’t possible, it’s that it costs too much. Argon arc welding is more cost-effective if deep penetration is needed to weld very thick materials.

Shanghai Jiesheng focuses on robot laser welding system, has rich experience, to provide customers with customized solutions.

Post time: Mar-21-2023