Factors Affecting the Reachability of Welding Robots

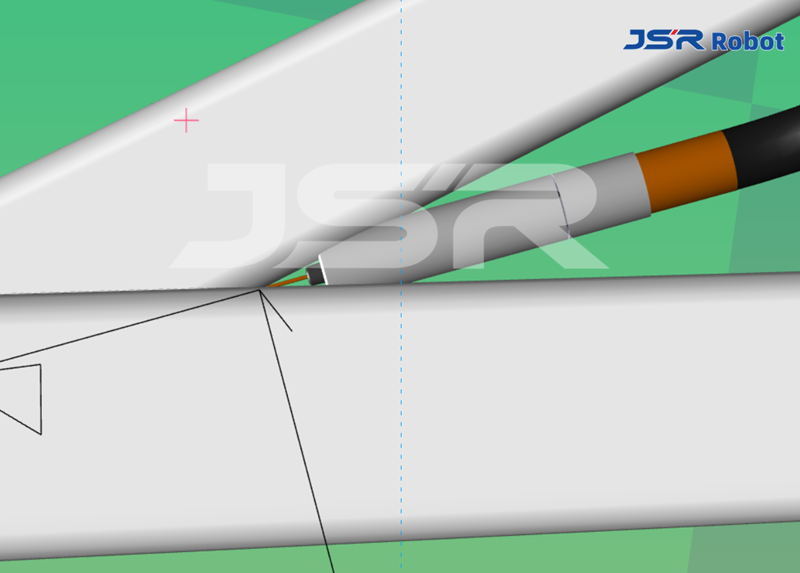

Recently, a customer of JSR was not sure whether the workpiece could be welded by a robot. Through the evaluation of our engineers, it was confirmed that the angle of the workpiece could not be entered by the robot and the angle needed to be modified.

Welding robots cannot reach every angle. Here are some influencing factors:

- Degrees of Freedom: Welding robots typically have 6 degrees of freedom, but sometimes this is not enough to reach all angles, especially in complex or confined welding areas.

- End-Effector: The size and shape of the welding torch can limit its range of motion in narrow spaces.

- Work Environment: Obstacles in the work environment can impede the robot’s movement, affecting its welding angles.

- Path Planning: The robot’s movement path needs to be planned to avoid collisions and ensure welding quality. Some complex paths may be difficult to achieve.

- Workpiece Design: The geometry and size of the workpiece affect the robot’s accessibility. Complex geometries may require special welding positions or multiple adjustments.

These factors impact the efficiency and quality of robotic welding and must be considered during task planning and equipment selection.

If any customer friends are unsure, please contact JSR. We have experienced and professional engineers to provide you with suggestions.

Post time: May-28-2024