1. Analyze and plan needs: Select the appropriate robot model and configuration based on production needs and product specifications.

2. Procurement and installation: Purchase robot equipment and install it on the production line. This process may involve customizing the machine to meet specific welding needs. If it is difficult to integrate it yourself, consult JSR, and the engineer will customized solution for you based on your needs.

3. Programming and debugging: Technicians program the robot to perform specific tasks and debug it to ensure that the robot can perform the work accurately.

4. Operation and maintenance: In daily production, the robot works according to the predetermined program.

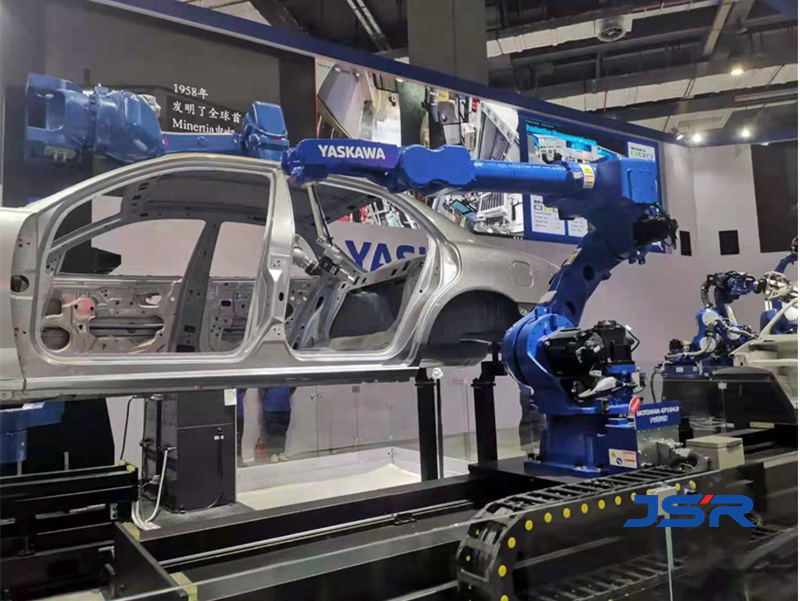

Advantages of Industrial Robots in Welding Automotive Automation Manufacturing

Improved safety: Robotic welding reduces workers’ exposure to harmful environments, including toxic fumes, heat, and noise.

Cost-effectiveness: Robots do not need to rest and can work around the clock, reducing labor costs and scrap due to human error. Despite the high initial investment, robots provide a high return on investment by increasing production efficiency and reducing scrap rates.

High efficiency and precision: Robots can consistently produce high-quality welded parts that meet the industry’s strict quality standards and can perform complex tasks such as welding, spraying, and surface treatment.

Versatility: Robots can be progammed to perform a variety of tasks, allowing for quick conversion of production processes when needed.

Post time: Jul-30-2024