In daily production process, pressure vessel is a kind of closed vessel that can withstand pressure. It plays an important role in many sectors such as industry, civil and military, as well as in many fields of scientific research. Pressure vessels are mostly used in the chemical industry and the petrochemical industry, mainly for heat transfer, mass transfer, reaction and other technological processes, as well as storage and transportation of gas under pressure or liquefied gas.

Welding is an important production process of pressure vessels. According to the difference of material, grade, chemical composition and welding performance of the welder, welding process involves arc welding, submerged arc welding, tungsten argon arc welding, MIG welding and so on. As a typical welding structure, the welding welds involved in pressure vessel welding are mostly complex space curves, and there are high requirements for welding in the production process. Improving the welding quality and mechanical automation level is of great significance to pressure vessel and even the whole welding industry.

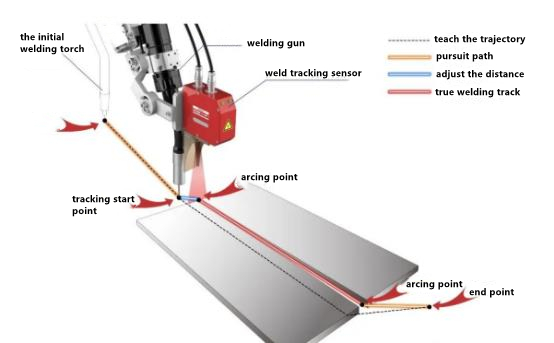

With the rapid development of automatic equipment, automatic welding technology of pressure vessel is becoming mature. Industrial robots are equipped with laser welding seam tracking system with height and lateral automatic tracking, and then realize automatic welding seam, and has become the mainstream trend, can solve the accuracy of workpiece incoming material, tooling accuracy are different degrees of error. Significantly reduce the teaching work of online robots.

Shanghai JieSheng autonomous robot integrated laser welding visual weld seam tracking system, can guide the robot real-time recognition of weld change or welding machine, automatic correction of welding line, products of high precision, stable running, reaction speed, widely used in different materials such as carbon steel, stainless steel, aluminum alloy pressure vessel welding, mature technical scheme, Support TIG, MAG, MIG, submerged arc welding, laser welding and other production processes.

Post time: Nov-09-2022