-

Yaskawa robot laser welding system 1/1.5/2/3 KW lasers

LASER WELDING

Structure of Robot Laser Welding System

1. Laser part (laser source, laser head, chiller, welding head, wire feeding part)

2. Yaskawa Robot arm

3. Auxiliary devices and workstations (single/double/three-station workbench, positioner, fixture, etc.)Automation laser welding machine / 6 Axis Robotic Laser Welding system / Laser Processing Robot Integrated System Solution

From automotive to aerospace – laser welding is suitable for many different areas of application. The decisive advantages of the process are the high welding speed and the low heat input.

-

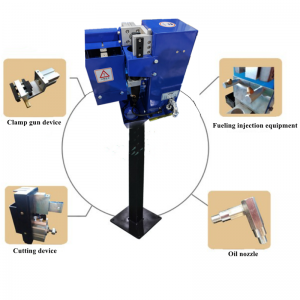

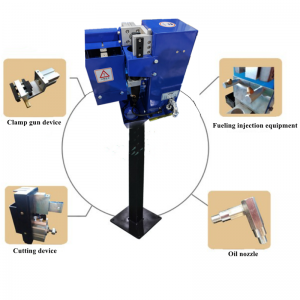

Welding Torch Cleaning Station

Cleaning Device for welding torch

Brand JSR Name welding torch cleaning station Device model JS-2000s The required air volume about 10L per second Program control Pneumatic Compressed air sourc Oil-free dry air 6bar Weight about 26kg (without base) 1. The gun cleaning and spraying design at the same position of the gun cleaning and cutting mechanism, the robot only needs-asignal to complete the gun cleaning and fuel injection actions. 2. Please ensure that the important components of the gun’s wire-cutting mechanism are protected by a high-quality casing to avoid the impact of collision, splash and dust. 1. Clear the gun It can effectively remove welding spatter attached to the nozzle for various robot welding. For severe “splash” paste, cleaning also has good results. The position of the welding nozzle during the work process is provided by the V-shaped block for precise positioning. 2. Spray The device can spray fine anti-spatter liquid in the nozzle to form a protective film, which effectively reduces the adhesion of welding spatter and prolongs the use time and accessories life. The clean environment benefits from the sealed spray space and the remaining oil collection device 3. Shearing The wire cutting device provides accurate and high-quality wire cutting work, removes the residual molten ball at the end of the welding wire, and ensures that the welding has a good starting Arc capability. Long service life and high degree of automation. -

YASKAWA Welder RD500S

Yaskawa robot weld RD500S MOTOWELD machine,Through the combination of the new digitally controlled welding power source and MOTOMAN, welding control that is more suitable for various welding methods is achieved, providing extremely high welding quality.

-

YASKAWA RD350S

High-quality welding can be achieved for both thin and medium-thick plates

-

TIG Welding Machine 400TX4

1.To switch the TIG welding mode by 4, to adjust the timing sequence by 5.

2.The gas pre-flow& post-flow time, current values, pulse frequency, duty cycle & slop time can be adjusted when Crater On is selected.

3.The pulse frequency adjustment range is 0.1-500Hz.

-

YASKAWA laser welding robot MOTOMAN-AR900

The small workpiece laser welding robot MOTOMAN-AR900, 6-axis vertical multi-joint type, maximum payload 7Kg, maximum horizontal elongation 927mm, suitable for YRC1000 control cabinet, uses include arc welding, laser processing, and handling. It has high stability and is suitable for many This kind of working environment, cost-effective, is the first choice of many companies MOTOMAN Yaskawa robot.

-

YASKAWA Automatic welding robot AR1440

Automatic welding robot AR1440, with high precision, high speed, low spatter function, 24 hours continuous operation, suitable for welding carbon steel, stainless steel, galvanized sheet, aluminum alloy and other materials, widely used in various auto parts, metals Furniture, fitness equipment, engineering machinery and other welding projects.

-

Yaskawa arc welding robot AR2010

The Yaskawa arc welding robot AR2010, with an arm span of 2010 mm, can carry a weight of 12KG, which maximizes the robot’s speed, freedom of movement and welding quality! The main installation methods of this arc welding robot are: floor type, upside-down type, wall-mounted type, and inclined type, which can meet the needs of users to the greatest extent.

-

Yaskawa spot welding robot MOTOMAN-SP165

The Yaskawa spot welding robot MOTOMAN-SP165 is a multi-function robot corresponding to small and medium welding guns. It is a 6-axis vertical multi-joint type, with a maximum load of 165Kg and a maximum range of 2702mm. It is suitable for YRC1000 control cabinets and uses for spot welding and transportation.

-

Yaskawa Spot Welding Robot SP210

The Yaskawa Spot Welding Robot Workstation SP210 has a maximum load of 210Kg and a maximum range of 2702mm. Its uses include spot welding and handling. It is suitable for electric power, electrical, machinery, and automobile industries. The most used field is the automatic assembly workshop of automobile bodies.

-

Yaskawa welding robot AR1730

Yaskawa welding robot AR1730 is used for arc welding, laser processing, handling, etc., with a maximum load of 25Kg and a maximum range of 1,730mm. Its uses include arc welding, laser processing, and handling.

-

Inverter DC pulse TIG arc welding machine VRTP400 (S-3)

TIG arc welding machine VRTP400 (S-3),has rich and diverse pulse mode functions, which can achieve better welding according to the shape of the workpiece;

© Copyright - 2020-2023 : All Rights Reserved.

Hot Products - SitemapWelding Robot, Yaskawa Spot Welding Robot, Yaskawa Painting Robot, Robot Palletizer, Palletizing Robot, Automatic Painting Robot,

Get the data sheet or free quote

Write your message here and send it to us