TIG Welding Machine 400TX4

| Modelnumber | YC-400TX4HGH | YC-400TX4HJE | ||

| Rated input voltage | V | 380 | 415 | |

| Number of phases | - | 3 | ||

| Rated input voltage | V | 380±10% | 415±10% | |

| Rated frequency | Hz | 50/60 | ||

|

Rated input |

T I G | kVA | 13.5 | 14.5 |

| Stick | 17.85 | 21.4 | ||

|

Rated Output |

T I G | kw | 12.8 | 12.4 |

| Stick | 17 | |||

| Power Factor | 0.95 | |||

| Rated No-Load Voltage | V | 73 | ||

| Output currentadjustable range | T I G | A | 4-400 | |

| Stick | A | 4-400 | ||

| Output voltage adjustable range | T I G | V | 10.2-26 | |

| Stick | V | 20.2-36 | ||

| Initial current | A | 4-400 | ||

| Pulse current | A | 4-400 | ||

| Crater current | A | 4-400 | ||

| Rated Duty Cycle | % | 60 | ||

| Control method | IGBT Inverter type | |||

| Cooling method | Forced air-cooling | |||

| High-frequency generator | Spark-oscillation type | |||

| Pre-flow time | s | 0-30 | ||

| Post-flow time | s | 0-30 | ||

| Up-slope time | s | 0-20 | ||

| Down-slope time | s | 0-20 | ||

| Arc spot time | s | 0.1-30 | ||

| Pulse frequency | Hz | 0.1-500 | ||

| Pulse width | % | 5-95 | ||

| Crater control process | Three mode(ON,OFF,REPEAT) | |||

| Dimensions (W×D×H) | mm | 340×558×603 | ||

| Mass | kg | 44 | ||

| Insulation class | - | 130℃ (reactor 180℃) | ||

| EMC classification | - | A | ||

| IP code | - | IP23 | ||

Stands for standard configurations

YT-158TP

(Applicable plate thickness: Max. 3.0mm)

YT-308TPW

(Applicable plate thickness: Max. 6.0mm)

YT-208T

(Applicable plate thickness: Max. 4.5mm)

YT-30TSW

(Applicable plate thickness: Max. 6.0mm)

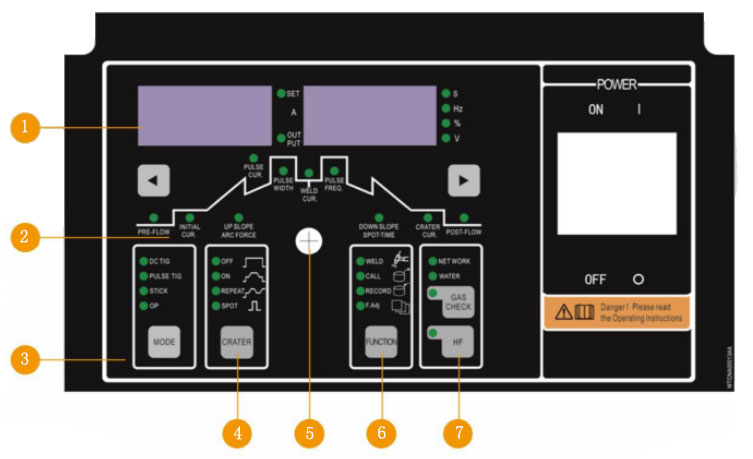

1. Multi-Functional Digital Display Meters

The values of current, voltage, time, Frequency, duty cycle, error code can be displayed.The minimum regulating unit is 0.1A

2. TIG Welding Mode

1). To switch the TIG welding mode by 4, to adjust the timing sequence by 5 .

2). The gas pre-flow& post-flow time, current values, pulse frequency, duty cycle & slop time can be adjusted when Crater On is selected.

3). The pulse frequency adjustment range is 0.1-500Hz.

3. Three Welding modes

1). DC TIG, DC PULSE & STICK.

2). When STICK welding is selected, both acid & alkaline electrodes are applicable and the arc- start & arc-force current can be adjusted.

4. TIG welding mode switch

1). the welding can be stopped by double press the torch switch when [REPEAT] is selected.

2). besides spot welding time, the slop can be adjusted too when[SPOT] is selected.

5. TIG welding mode switch

Digital encoder, rotate to adjust, press to confirm

1). In order to consider the reliability of using in the tough environment, the machine's inside structure is horizontal.

2). The PC Board's circuit control loop has a separate sealing chamber. the PC Board is vertically installed in order to avoid the dust heap up.

3). Large axial flow fan, independent air duct, good heat dissipation

4). Multi-protectiond: primary overvoltage, undervoltage, open-phase protection; secondary overcurrent, electrode short circuit, water- shjortage protection, temperature switch protection, etc.

6.Function Settings

1. 100 groups parameters can be stored & recalled.

2. [F.Adj] can set/adjust more functions

Current limitation function: the range is 50-400A

Anti-shock function: this function can be selected when stick welding in the wet or cramped environment conditions. The factory default is OFF.

Arc-start adjustment function: the arc-start current and time can be adjustable.

Short circuit alarming: it will alarm when the tungsten electrode and the workpiece are short circuit , it will prevent the damange of the tungsten electrode. burning(please refer to the operation manual for more settings)

7.Arc-start setting

High frequency arc-start and pull arc-start , are used even in the areas where the high frequency is forbidden.